在线播放黄色网,在线观看的日韩av不卡,腿张开再深点好爽在线看,久久综合色综合

Main Business

- Welding materials

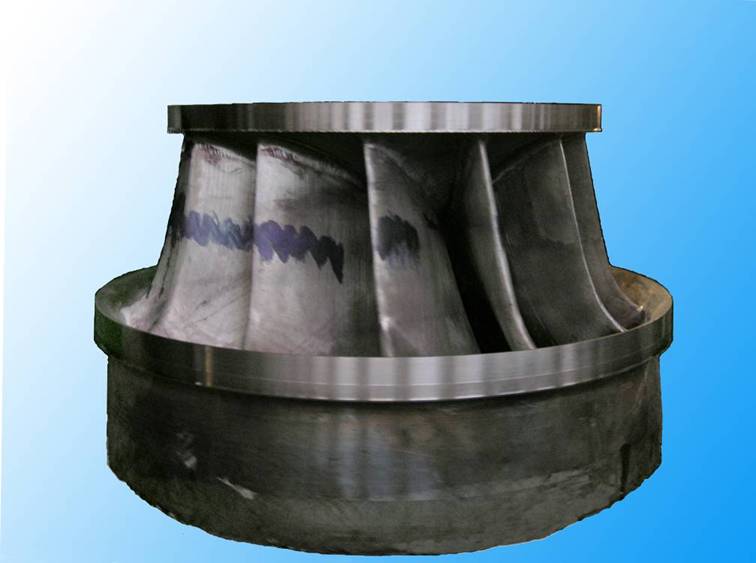

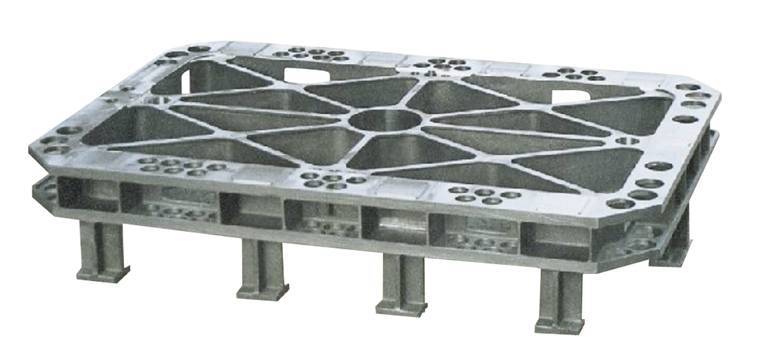

- Casting

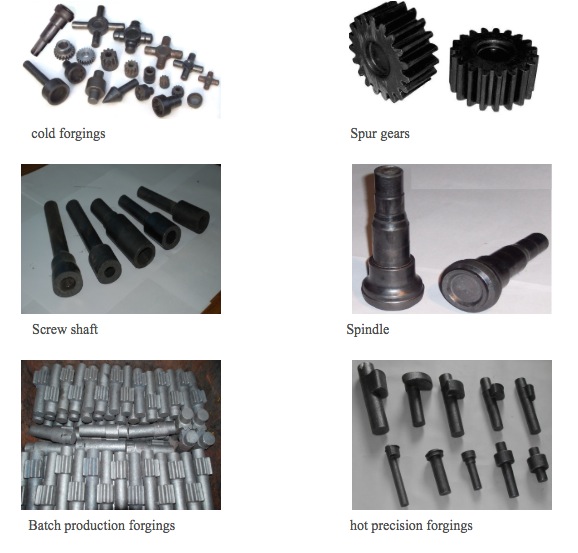

- Forging

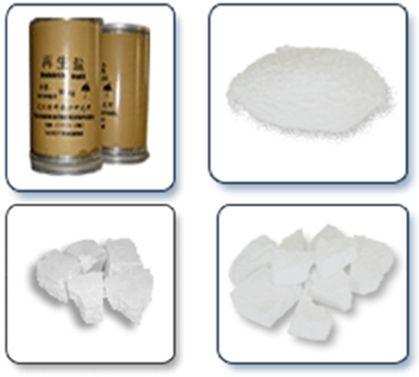

- Surface engineering materials

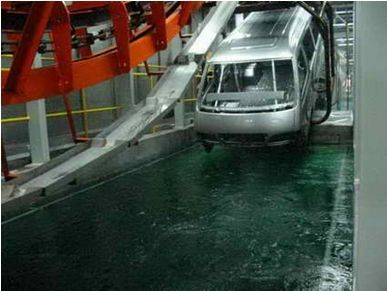

- Coating

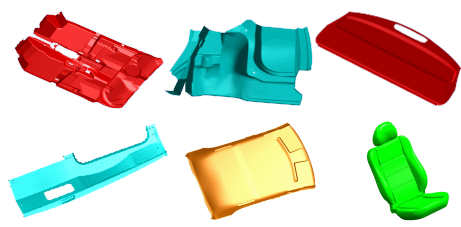

- Mould materials

- Other materials

-

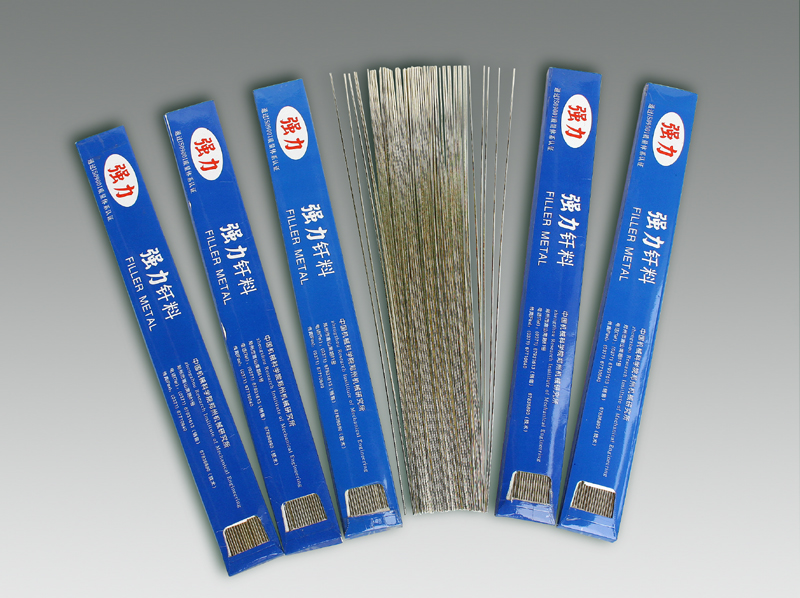

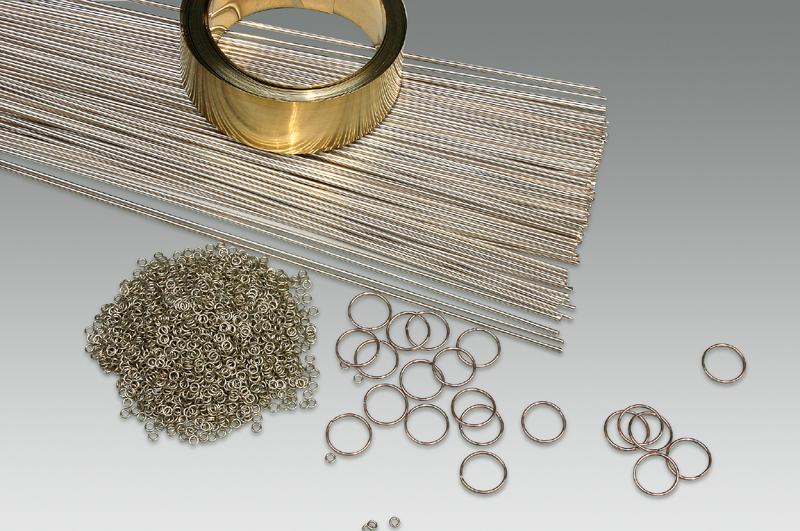

Brazing filler metals

Being endued with advanced equipment for production, test and experiment, We are engaged in designing and processing businesses of all kinds of various brazing assembliies and developing business of customized filler metals. There are 6 series, more than 300 brands, and about 2000 species of filler metals, including silver base filler metals, copper base filler metals, aluminum base filler metals, tin-lead base filler metals, powder filler metals, and sandwich filler metals. Brazing filler metals can be supplied in various forms, such as wire, rod, tape, sheet, ring, powder, paste, foil, preforming, and flux-cored forms, and widely applied in industry of aerospace, electric power, vehicle, diamond tools, carbide tools, petroleum exploitation tools, coal drilling tools, refrigeration system, spectacle frames, motor, lamp, etc.

-

1. Filler metals for diamond tools

Filler metals for diamond tools fall into 4 categories: (1) Silver base filler metals are used to braze diamond cutting tools, saw blades, tiles, grinding plates, which are applied in stone, ceramic or cement concrete pavement processing. (2) Nickel base filler metals are suitable for the brazed monolayer diamond tools in vacuum brazing. (3) Zn-Cd solders are mainly used to braze honing stone. (4) Copper base brazing filler metals are used for diamond tools which service at elevated temperatures.

-

2. Filler metals for carbide tools

Filler metals for carbide tools fall into 4 categories: (1) Copper base brazing filler metals are used for diamond tools which service at elevated temperatures. (2) Silver base filler metals have good wetability, fiiability , and high fatigue resistance. (3) Sandwich filler metals show good impact resistance, higher high-temperature strength, and contribute to avoid the crack of carbide. (4) Powder filler metals are applied to automatic brazing.

-

3. Filler metals for drilling tool

There are 5 categories of filler metals for drilling tool. (1) Silver base filler metals with cadmium melt at low temperature, and are usually used to braze auxiliary tools. (2) Cadmium-free silver base filler metals satisfied the requirements of environmental protection, are mainly used for miniature drills. (3) BAg series are mainly used for PDC drilling bits. (4) Copper base brazing filler metals are able to form high strength joints with higher brazing temperatures, are mainly used for carbide drills; (5) Maceration alloy is an important material in the coldpressed maceration, pressureless maceration and PDC bit manufacture.

-

4. Filler metals for spectacle frames

To make sure filler metals meets the strict requirement of spectacle frames, the chemical contents of filler metals for spectacle frames should be quite pure and stable and the measurement must be accurate and consistent. There are 3 categories of filler metals for spectacle frames. (1) GS1××series are used for brazing stainless steel and monel. (2) GS5××series are suitable for brass and copper-nickel alloy. (3) TH××series are applied for titanium alloy.

-

5. Filler metals for pipeline in refrigeration system

Under ISO9001:2000 system and IECQ-HSPM(QC080000)system, products have been passed SGS environmental test, all of them comply with the direction of “RoHS”. Filler metals for pipeline in refrigeration system fall into 3 categories: (1) New cadmium-free silver brazing filler metals are conformed ROHS requirement. (2) Traditional silver brazing filler metals are used for brazing Bundy tube with dense joint. (3) Cu-P filler metals are applied to braze copper tube with gas flux.

-

7. Copper base brazing filler metals

Copper base brazing filler metals fall into 4 categories: (1) Cu-Zn alloy are mainly used for argon arc welding of copper alloys and overlaying of steel. (2) Cu-Zn-Mn(Co/Ni)alloys are mainly used for carbide tools. (3) Cu-Ni-Mn alloys are applied for making high temperature and high strength workpiece with good fluidity and plasticity. (4) Cu-Si alloys are used for argon arc brazing. (5)Cu-Mn-Fe and Cu-Sn alloys are mainly used for furnace brazing of steel. (6) Cu-P alloys are used for brazing copper subassenmblies with good fluidity.

-

8. Filler metals for copper aluminium joint

Filler metals for copper aluminium joint is a kind of seamless flux-cored wire with consistent filling coefficient, its mainly element ingredients are zinc, aluminium, copper, and noncorrosive fluoride, and the welding processing property, mechanical properties and electrical conductivity are better than Zn-Cd and Zn-Sn-Cu series. There are 5 categories of filler metals for copper aluminium joint, such as Al-Si, Zn-Al, Zn-Al-Si, Zn-Al-Ag and Zn-Al-Cu. In addition Zn-Al and Zn-Al-Ag are the most widely used industrial one now. Filler metals for copper aluminium joint have a wide application in the field of electricity and electrical equipment, stainless steel products, refrigeration system, hardware product. Filler metals for copper aluminium joint can be preserved for long-term without any antiseptic, and be bent into a ring without powder loss.

China Academy of Machinery Science and Technology (CAM), founded in 1956, is...

micro-blog

Copyright China Academy of Machinery Science & Technology Support:xinocheng